Solution

Contact Us

E-mail:

export@syhuali.com

WhatsApp:

+86-15142051054

Tel:

+86-24-85818396

Address:

10A-2, 5th Road, Tiexi District, Shenyang, China

Green Switch Solution

Green Switchgear Technology

● Using vacuum interrupter for breaking. No SF6 gas used, and no decomposition of toxic substances.

● Insulated by clean air.

● The switchgear is completely free of SF6 gas usage and emission, achieving emission reduction and environmental protection purposes.

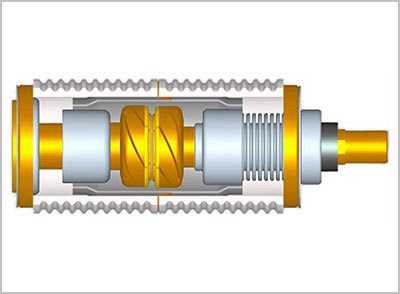

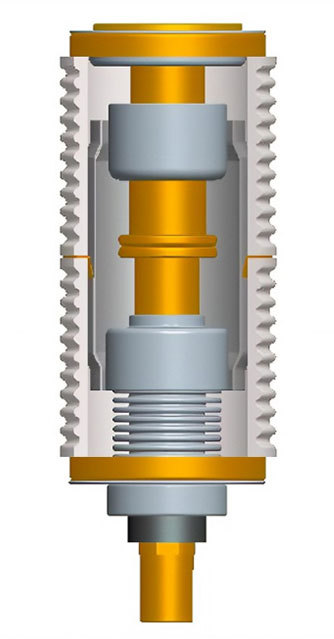

vacuum interrupter

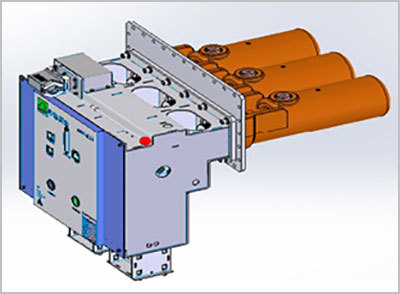

vacuum circuit breaker

How does the green switchgear achieve emission reduction?

For breaking:

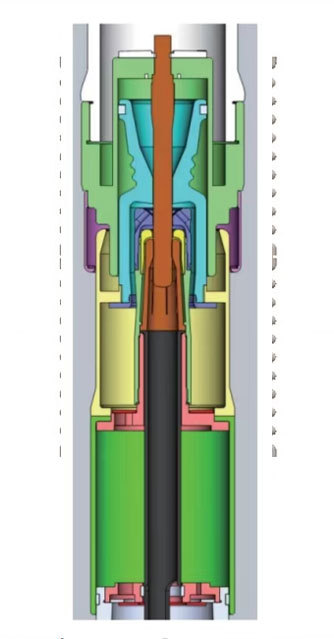

The SF6 switch interrupter using high pressure SF6 gas. The green switch interrupter using vacuum.

SF6 interrupter

vacuum interrupter

For insulation:

The SF6 switch using high pressure SF6 gas for insulating. The green switch using clean air for insulating.

Insulating Gas

Green Switchgear Technology

1. No SF6 gas usage and emissions, reducing green house gas emissions;

2. No toxic gas produced, harmless to people and the environment;

3. Miniaturized, the volume is half of the traditional switchgear.

4. The main parts are sealed in stainless steel tank, maintenance-free.

5. Especially suitable for sandstorm, coastal corrosion environment, underground and indoor space.

6. Products for 12KV、24KV、40.5KV、72.5KV、 145KV。

What Is SF6 Gas?

● One of the main factors that the transmission equipment industry's impact on global climate change comes from the usage and emission of SF6 gas.

● Due to its good insulation and arc extinguishing efforts, 80% of SF6 gas is used in switchgears.

● The continuous increase of power grid has resulted in the increase of the usage and emission of SF6 gas.

Greenhouse effect of SF6

● SF6 is one of the six emission reduction greenhouse gases stipulated by the Montreal Protocol and the Tokyo Protocol;

● Its global warming potential (GWP) is 25,200 times of CO2. That is, the emission of one ton of SF6 is equivalent to the emission of 25,200 tons of CO2.

● SF6 gas has excellent stability at room temperature and has an atmospheric life of up to 3200 years

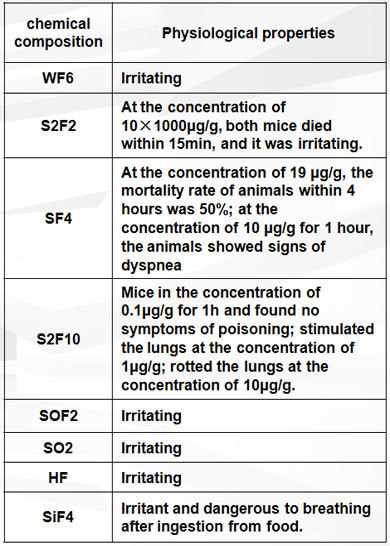

Environmental Effects of SF6

After SF6 is decomposed through arc discharge, various toxic fluorides such as SF4, S2F2, S2F10 are produced, which seriously endangers human health and the environment.

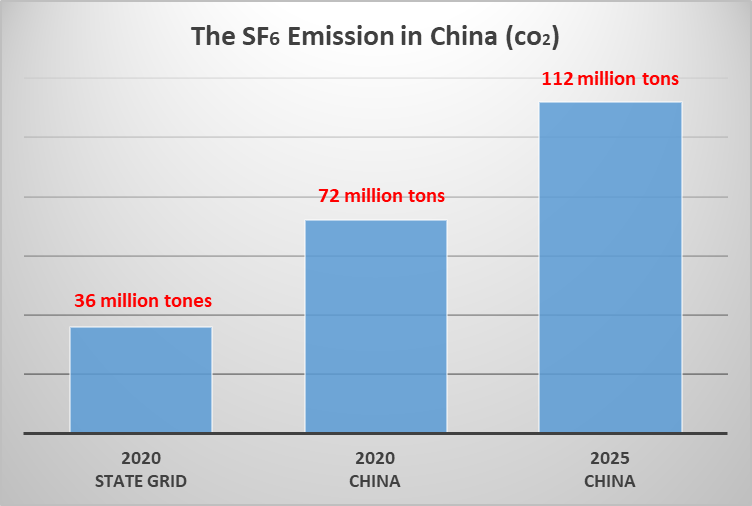

SF6 Emission in China

According to the data in 2020, if no any emission control solution, the total annual emission of SF6 from the State Grid Corporation of China was about 1,428 tons, corresponding to the emission of 36 million tons of CO2 equivalent.

China’s total SF6 annual emission in 2020 was about 2,856 tons, equivalent to more than 72 million tons of CO2 emissions. It is predicted that China's total annual SF6 emission in 2025 will be about 4,454 tons, corresponding to the emission of 112 million tons of CO2 equivalent.

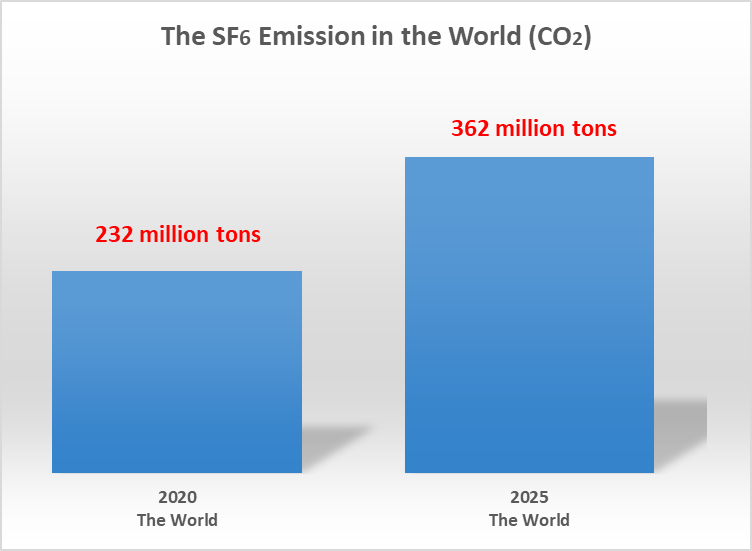

SF6 Emission in the World

According to the data, that China's electricity consumption accounts for 31% of the world's total, it is predicted that the world’s SF6 emission in 2020 was about 9,213 tons, equivalent to 232 million tons of CO2, and the world’s SF6 emissions in 2025 will be about 14,368 tons, equivalent to 362 million tons of CO2.

International Greenhouse Gas Control Policies

The international communities issued the greenhouse gas control policies on the basis of “The Paris Agreements”. For example, the European Union, GCC, and the United States set up the target of carbon neutrality is by 2050.

SF6 Emission Control Policies

● The SF6 Control plan issued by the State Grid Corporation of China in 2022 expects that SF6 will peak in 2025, and will be neutralized in 2050.

● In March 2023, the European Parliament announced to ban the greenhouse gases SF6 totally in switchgear after 2032.

● In the United States, Senate Bill 32 (2016), passed in 2016, required the grid to reduce greenhouse gas emissions such as SF6 by 40 percent below 1990 levels by 2030.

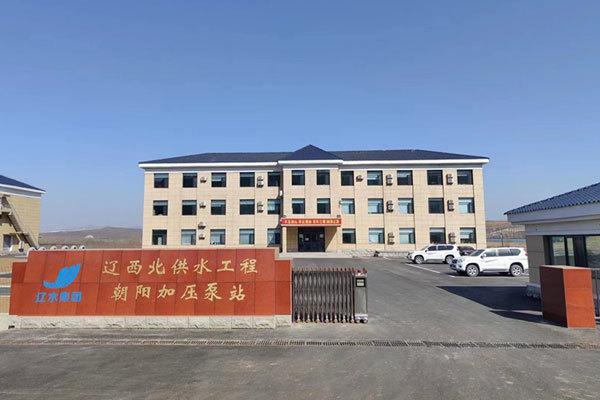

SF6 reduction project case one

Liaoning Northwest Water Supply Co., Ltd. purchased 15 sets of outdoor green HG6-72.5KV H-GIS products from Shenyang Huade High-tech Electric in 2020. Using traditional SF6 insulated switchgears instead, 100kg SF6 gas used in a single set, and the total 1500kg SF6 gas used in the project.

According to the "Guidelines for the Preparation of Provincial GHG Emission Inventories" and the United Nations Climate Change Committee emission reduction methodology AM01119, compared with the traditional products, the SF6 emission reduction of the project cycle in the production process, use process, and disposal process is 65.25kg per year, equivalent to 1644 tons of CO2 per year. The total emission reduction of the project cycle for 20 years is 32,880 tons of CO2.

Total Carbon Reduction: 32880 Tons

SF6 reduction project case two

Zhangjiakou city green electric heating project for Beijing Winter Olympics purchased 62 sets of green HG3-40.5KV products from Shenyang Huade High-tech Electric in 2019. Using traditional SF6 insulated switchgears instead, 4.4kg SF6 gas used in a single set, and the total 272.8kg SF6 gas used in the project.

According to the "Guidelines for the Preparation of Provincial GHG Emission Inventories" and the United Nations Climate Change Committee emission reduction methodology AM01119, compared with the traditional products, the SF6 emission reduction of the project cycle in the production process, use process, and disposal process is 11.73kg per year, equivalent to 295 tons of CO2 per year. The total emission reduction of the project cycle for 20 years is 5912 tons of CO2.

Total Carbon Reduction: 5912 Tons

SF6 reduction project case three

State Grid Corporation of China in Qinghai Xining city branch purchased 44 sets of green HG4-12KV products from Shenyang Huade High-tech Electric in 2016. Using traditional SF6 insulated switchgears instead, 2.5kg SF6 gas used in a single set, and the total 110kg SF6 gas used in the project.

According to the "Guidelines for the Preparation of Provincial GHG Emission Inventories" and the United Nations Climate Change Committee emission reduction methodology AM01119, compared with the traditional products, the SF6 emission reduction of the project cycle in the production process, use process, and disposal process is 4.785kg per year, equivalent to 121 tons of CO2 per year. The total emission reduction of the project cycle for 20 years is 2412 tons of CO2.

Total Carbon Reduction: 2412 Tons